Concrete is a composite material widely used in construction due to its strength and durability. Its composition primarily includes cement, water, and aggregates, but it often requires admixtures to enhance its performance. These admixtures can improve the workability, durability, and overall quality of concrete. Let’s delve into some typical admixtures found in concrete.

(The Usual Suspects: Typical Admixtures in Concrete Revealed)

### 1. Superplasticizers

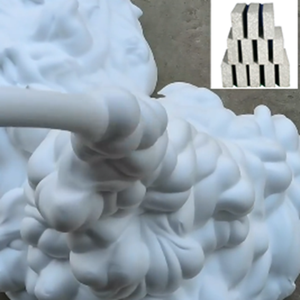

Superplasticizers, also known as plasticizers, are the most common admixture in concrete. They reduce the amount of water needed for proper mixing, leading to a more uniform and dense mixture. This results in higher strength and improved workability, especially in large-scale structures where high volumes of concrete are required. The most common type is polyacrylamide-based superplasticizer.

### 2. Air-entraining Admixtures

Air entrainment involves the addition of small bubbles within the concrete matrix. These bubbles act as micro-insulators, reducing heat loss during the curing process and preventing frost damage. This makes air-entrained concrete particularly suitable for cold climates or for use in areas prone to freezing conditions. Sodium lauryl sulfate (SLS) is a common air-entraining agent.

### 3. Retarders

Concrete hardens through a chemical reaction called hydration, which is accelerated by temperature. Retarders slow down this process, allowing for better placement and finishing of the concrete. This is particularly useful when working with large pours that need time to settle before setting. Calcium nitrate is one type of retarder commonly used.

### 4. Accelerators

Contrary to retarders, accelerators speed up the hydration process, enabling quicker setting times. This is beneficial in cold weather or when rapid hardening is necessary to meet project deadlines. Sodium silicate is a common accelerator.

### 5. Fiber Reinforcements

Fibers, such as glass or steel, are added to concrete to increase its tensile strength and ductility. They prevent cracking under tension, improving the durability of the structure. This admixture is particularly useful in structures subjected to cyclic loading or in areas with high humidity.

### 6. Colorants

Concrete colorants are used to achieve aesthetically pleasing designs without altering its structural properties. These can be organic dyes or inorganic pigments, providing a wide range of color options. This admixture is purely decorative and does not impact the concrete’s performance.

### 7. Rust Preventives

In reinforced concrete, rust inhibitors are added to prevent corrosion of steel reinforcement bars. This helps maintain the structural integrity of the concrete over time, ensuring the longevity of the building or structure.

(The Usual Suspects: Typical Admixtures in Concrete Revealed)

These admixtures are carefully selected and measured to ensure they complement each other and do not negatively affect the final product. Proper use of these admixtures can significantly enhance the performance and longevity of concrete structures.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)