Concrete is a versatile material used extensively in construction due to its strength, durability, and ability to be customized with various additives and admixtures. These substances enhance the properties of concrete beyond its inherent characteristics, enabling it to meet specific project requirements. Here’s an overview of some common additives and admixtures used in concrete.

(Beyond the Basics: Other Additives and Admixtures in Concrete (Duplicate))

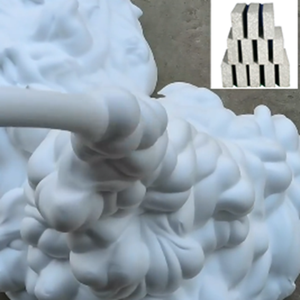

**Air-entraining admixtures** – These substances introduce tiny air bubbles into the concrete mix during the batching process. The air entrapped acts as a buffer against freeze-thaw cycles, protecting the concrete from damage caused by ice expansion. Air-entraining admixtures also improve workability and reduce cracking.

**Superplasticizers** – These are high-performance admixtures that significantly increase the workability of concrete without increasing water content or compromising its strength. Superplasticizers achieve this by reducing the surface tension between water and cement particles, allowing them to mix more efficiently. This results in a smoother, more uniform concrete with reduced porosity and improved durability.

**Retarders** – Retarders are used to slow down the initial setting time of concrete, particularly in large pours where the entire volume needs to set uniformly. This allows for better control over the placement and finishing processes, reducing the risk of thermal cracking and improving overall workability.

**Accelerators** – Contrary to retarders, accelerators speed up the hydration process of concrete. They are often used in cold weather conditions or when rapid setting is required, such as in bridge decks or other time-sensitive projects. Accelerators can also help mitigate the effects of cold temperatures on concrete performance.

**Colorants** – Concrete colorants are used to impart color to the finished product without altering its composition. They can be applied directly to the mix or used as a topping coat. Colorants offer designers flexibility in creating aesthetically pleasing structures while maintaining the structural integrity and performance of the concrete.

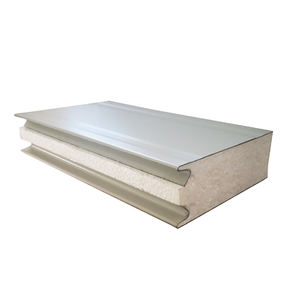

**Fiber-reinforced concrete** – Fibers, typically made of steel, glass, or carbon, are added to concrete to enhance its tensile strength and ductility. This results in a more resilient material capable of absorbing stress without fracturing, leading to longer-lasting structures.

**Water-reducing admixtures** – Also known as plasticizers, these admixtures reduce the amount of water needed to achieve a workable consistency in concrete. By minimizing water content, they improve the density and strength of the final product, making it more suitable for high-performance applications.

(Beyond the Basics: Other Additives and Admixtures in Concrete (Duplicate))

Each type of additive or admixture serves a unique purpose, enhancing the functionality, efficiency, and aesthetics of concrete projects. By carefully selecting and incorporating these materials, engineers and constructors can tailor concrete to meet the specific demands of various applications, ensuring both structural integrity and long-term performance.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)