Magnetic oxides, also known as ferrites, are compounds of iron oxide combined with metals like cobalt, nickel, or manganese. These materials exhibit unique magnetic properties, making them indispensable in modern technology. Their ability to retain magnetism while resisting corrosion sets them apart from pure metal magnets. Common types include soft ferrites (used in electronics) and hard ferrites (found in permanent magnets).

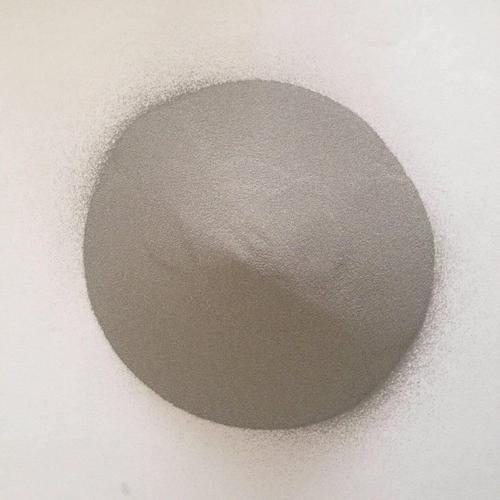

(magnetic oxide)

Iron oxide (Fe₃O₄), or magnetite, is a naturally occurring magnetic oxide. It’s widely studied for its spinel structure, where metal ions occupy specific lattice sites, enabling strong magnetic interactions. Synthetic variants, like cobalt ferrite (CoFe₂O₄), enhance performance for specialized applications.

Magnetic oxides dominate electronics due to their high electrical resistance and low energy loss. They’re key in transformers, inductors, and high-frequency devices. In data storage, ferrites are used in magnetic recording media and read/write heads. Their role in shielding electromagnetic interference (EMI) protects sensitive equipment.

Medical applications include MRI contrast agents and drug delivery systems, where magnetic nanoparticles (often iron oxide) are guided to target areas using external magnetic fields. Environmental uses involve water purification, as magnetic oxides adsorb pollutants and are easily separated via magnets.

Research focuses on improving magnetic oxide efficiency for renewable energy tech. For instance, they’re integral to power converters in wind turbines and solar inverters. Spintronics, a field leveraging electron spin for data processing, relies on magnetic oxides for next-gen memory devices.

Sustainability drives interest in recyclable magnetic materials. Their stability and abundance make them eco-friendly alternatives to rare-earth magnets. Challenges remain in optimizing cost and performance, but advancements in nanotechnology and material science continue to expand their potential.

(magnetic oxide)

In summary, magnetic oxides bridge traditional engineering and cutting-edge innovation. From everyday electronics to life-saving medical tools, their versatility ensures they remain at the forefront of technological progress.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)